Improve Productivity and Lower the Cost of Secondary Machining Operations

through high concentricity. Holding close concentricity tolerances during each machining operation not only reduces scrap rates, but also allows you to leave less material for finishing operations. Therefore, you reduce cycle time and improve tool life of finishing operations. And MicroCentric air chucks give you the capability to improve workpiece roundness, squareness, and parallelism as well.

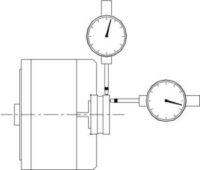

Accuracy within 0.00005" TIR

A standard repeating accuracy of 0.00005" TIR. This means the radial and lateral runout of your workpieces will be held within 0.00005" (0.0012 mm). Models with higher accuracy are also available.

Over 30 Years of Advanced Design and Engineering

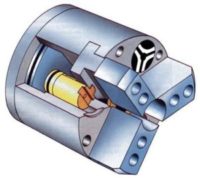

Made MicroCentric the world's leading builder of precision chucks. MicroCentric air chucks are a sliding jaw, self-contained design. Air is supplied to the chuck by a rotating air tube assembly, or directly in the side of the chuck body for stationary applications. Air chucks can be actuated by a manual or electronic solenoid valve.

Clamping force is adjusted by varying the input air pressure.

MicroCentric air chucks are an open center design with separate actuators for each base jaw. They feature a meehanite chuck body with hardened steel actuators and base jaws. All components are precision ground, and the base jaws are lapped to fit with each individual jaw slot, assuring high repeating accuracy and minimal jaw lift as the chuck clamps. MicroCentric air chucks are double acting for both ID and OD applications.

To learn more, visit the catalog.